Adamatic ADR2 Bread & Roll Make Up Line – Rebuilt

Extremely accurate scaling and rounding. Production speeds up to 7,200 pieces per hour, as a 3 pocket. Typical accuracy runs +/- 2%. Scaling and production weights may vary with different dough consistencies.

Includes:

- Rebuilt Adamatic Intermediate Combi Proofer

- Refurbished 2 Pocket Roll Stamper, Model CG/102-83

- New Glimek Bread and Roll Molder, Model LR67

Standard Features:

- Speeds up to 40 strokes per minute with standard gear ratio

- Fully adjustable hydraulic main piston, assuring accurate scaling with minimal dough punishment

- Variable speed and rounding control

- Adjustable gravity feed oiling system

- Flour duster

- Chute to Drum for two pocket Piston & Liners

- Simple weight adjustment

- Stainless steel covers. Any cover that does not require a tool or threaded cover holder to remove, uses magnetic interlocks for safety. Magnetic contacts can be overridden by using an exterior magnet.

- BISSC approved; easy to clean and maintain

- UL listed control panel

- ADR tool group

Specifications:

- Electrical: 220v/60hz/3ph @20 amps

- Shipping weight: 2,150 lbs

Price includes the following Scaling Pistons & Rounding Drums (can be changed)

- Piston/Liner 1.5-4.5oz @ 2 pkt & 10-19oz @ 1 pkt – NEW

- Rounding Drum 2 pocket 1.75-2.75 oz (approximate scaling weights) – USED

Rebuilt Adamatic Intermediate Combi Proofer

Model CP 44/6 Inlet RH front “U” Shape Layout

- Proof Times:

- Rolls: 3.3 to 7 minute proof

- Breads: 8 to 21 minute proof

- Tray capacity, 24 oz. (535 gr.)

- Heavy-duty square tubing, welded construction

- Heavy-duty roller chain

- Clean-out door at proofer discharge

- Sliding Plexiglas® inspection windows

- Flour duster at proofer infeed

- Sanitary construction

- High impact plastic trays with nylon mesh inserts

- Cross conveyor 9.5”Wx65.75”L, LH

- Flour Duster Assy. Proofer Inlet

- Driven from Divider/Rounder

- Voltage: 208-230v/3 ph/60 Hz. 10 Amps

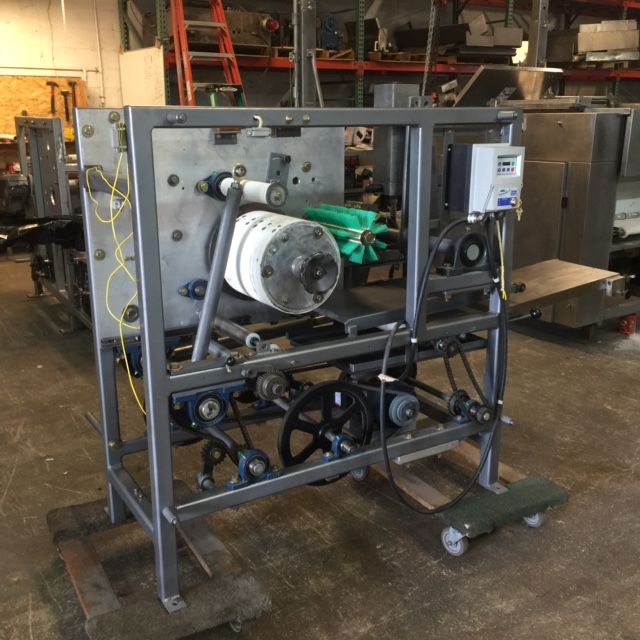

Refurbished 2 Pocket Roll Stamper, Model CG/102-83

- Stamper up to 4800 rolls per hour. Weight ranges from 1.0 to 4.0 oz.

- Includes one set of Kaiser Roll dies

- Interlocked safety switches

- Easily changeable cutting dies

- Adjustable gravity feed oiling system

- Fold up discharge conveyor

- Heavy-duty casters

- Holder for extra die sets

- Voltage 115-120v/1 ph/60 Hz.. 75 hp motor (other voltages available)

New Glimek Bread and Roll Molder, Model LR67

Molds up to 3000 rolls or breads per hour, up to 56 oz. (1600 gr.) depending on product specification

- Heavy-duty for high-speed production.

- Two (2) adjustable pairs of sheeting rollers.

- Universal adjustable pressure board.

- Adjustable Side Guides (Parallel side guides available for additional charge)

- Working width: 25.5” (650 mm)

- Interlocked safety switches

- Interlocked hopper safety cage

- Adjustable side guides

- Voltage: 208-230v/3 ph/60 Hz. 10 Amps

- Dimensions 87” (2210 mm) L, x 40” (1016 mm) W, x 59.5” (1512 mm) H