BEW Size #20, 2000LB Horizontal Dough Mixer

JH Day Hercules #16 Hroizontal Mixer

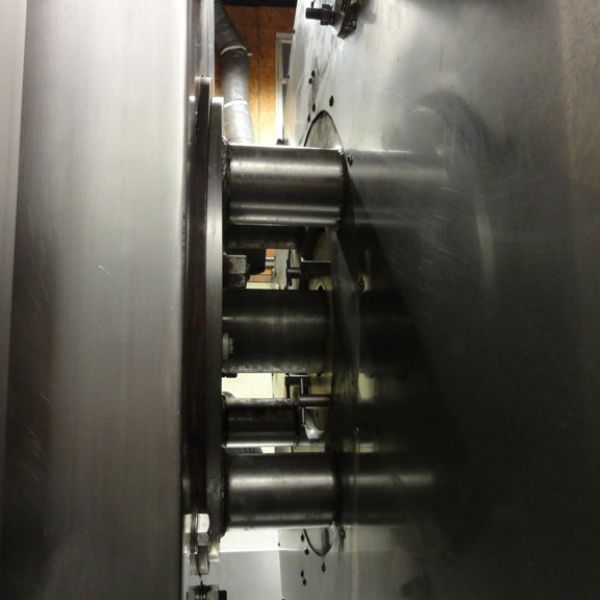

EW size #20, 2000 lb nominal mixing capacity, horizontal, over-tilt dough mixer. It currently has a 100/50 HP main drive motor in 460 volt 3 ph 60 cycles. Is has a hydraulic tilt package for the bowl tilting. The main agitators are three roller bar type with the stretcher bar inside the bowl. The bowl canopy has the flour inlet opening [no slide gate included] with two [2] liquid inlet fittings. The attached Shaffer mixer dimensional chart for the #20 mixer is accurate for this mixer, however the BEW mixer is presently on 10” tall feet instead of the standard 6” tall feet as shown, so dimensions C, D are actually 4” taller than the standard dimension as shown. This mixer came out of a plant that was mixing soft bun and English muffin dough, and is was in solid running condition when we received it.

Recently Completed Work:

- Installed new shaft bearings [2] in the main mixing motor

- Installed new main shaft seals on the main agitator shaft

- Drained and refilled both the rear-end drive and the hydraulic package with new oil

- Re-pinned the right side spider to the main shaft [as it had some play in the pins when we received it].

- Test ran the machine through the electrical controls…all runs as designed.

As an option, we can do the following additional work on this mixer:

- Fabricate and install four [4] new S/S mixer mounting feet [in lieu of the existing “mild steel” feet, to be all S/S and 6” tall.

- Pressure test the bowl mixer jacket to be free of leaks and repair as needed if any exist.

- Fabricate and install eight [8] new S/S roller bar and breaker bar sleeves in S/S to replace the mild steel ones on the mixer now.

- Check the mixer agitator speed to be 70 RPM on high and 35 RPM on low.

- Reinforce the upper back portion of the mixer bowl with S/S structural cross members [for added strength to mix firm dough]

- Insulate the mixer bowl with closed cell chiller barrel wrap [Armaflex or equal], as the bowl is not presently insulated.

- Clean existing main electrical starter contactor pads [currently in good condition as per our inspection]

- Re-wire the electrical panel and operator’s station with new wiring, to a proper AutoCAD drawn wiring print, which meets 2012 electrical codes and safeties.

- Recondition the hydraulic pack with new oil added

- Check rear end drive with new input and output seals installed, check backlash tolerances to be proper.

- Replace “U” joint drives on main motor

- Test run the mixer and controls in our shop