Description

Manufacturer Info

The fryer is provided with a conveyor assembly that moves product through a bath of cooking oil medium that is maintained at a process temperature during the dwell frying time.

Kettle is constructed of heavy duty plate stainless steel material with heat expansion joints for controlled flexing, high efficiency immersion tube burner, heat to be transferred via direct oil contact to outer burner tube, integrated oil manifolds for full flow oil circulating system with special bottom sweep system using oil pressure jets to reduce buildup of product on bottom of kettle. V-shape tank for superior oil drainage and debris flow.

Pre-mix burner system with flame supervision safeguards, modulating temperature controls included with package.

Temperature control thermocouples located in the main frying tank kettle.

Electronic variable speed control to govern product flow

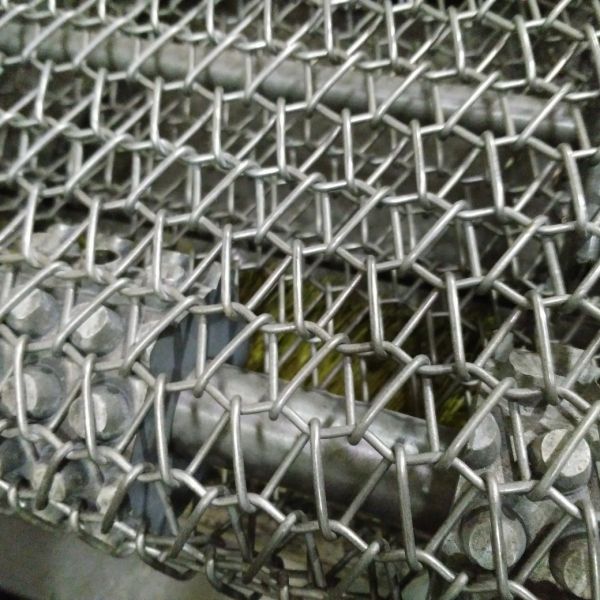

For Tortilla Chips and Casero Tostada, belt to close in-feed edge to move product forward under complete submersion via top conveyor belt unit is also to have bottom carry over belting for positive transport of fried Tortilla Chip and Casero Tostada product. Tostada to be hand fed into fryer input side.

Positive drive conveyor belt fabricated of stainless with a heavy duty chain on both edges, curtain belt flights attached every 1 O” to provide a positive flow of product.

Stainless traction flights on output conveyor belt for removal of fried product.

Discharge conveyor to extend to bottom of kettle with independent belt speed control.

Mechanical lifting assembly for elevating and lowering conveyor assembly insert from main tank.

Liquid level audible alarm for notification of manual gravity fill from holding tank to main frying tank.

Hood construction equipped with two output vents for optimum steam removal along with recovery drip moisture pan and drain.

Freestanding stainless steel control panel includes on/off controls, temperature and Limi-trol safety high limit temperature sensor, Top submersion belt speed controls, hoist lift control winch, and pilot light for flame monitoring status.

Heavy duty oil circulating pump along with industrial type continuous electrical motor.

Stationary crumb cylinder catch, included to catch large crumb particles before they enter disk filter or when filter system is supplied. Unit consists of a stainless steel cylinder containing a removable perforated basket designed to manually remove larger crumbs from system removal, the crumb cylinder catch is attached to the oil outlet of fryer kettle.

Safety

Magnetic interlock on removable guards over drive sprockets and gears

On/off controls, temperature and limi-trol safety high limit temperature sensors, paddle and pilot light for flame monitoring status.

Emergency stop button for quick and easy stopping.

Note: To be supplied by customer as follows; all field handling, placing and reconnecting of units. Piping required for water, frying oil, gas, drain lines, and compressed air, and its installation. Field wiring of pumps, conveyor motors, and blower motors, as required. Exhaust stacks and inducers for the fryer, and their installation. C02 or other Fire Protection System, as required by local and federal code

“NSF” I “ETL” listed

Proudly Made in the “USA”