Saltek 3 Row Pita Bread Line

Features:

- Manufacturing Year 2004

- Barely used

- Includes all original equipment in good condition

- Saltek 3 Row Pita Bread Production Line

- Output Capacity: Up to 9000 loaves/hour

- Dough Divider – With S/S bowl which can be opened to enable cleaning of endless screws, and a rotating S/S scraper/agitator to prevent the dough from developing air pockets

- Model SADR-3AL

- Stainless Steel

- 3 Extruding Nozzles (3 rows across output) with interchangeable adapters to control product scaling.

- Dough balls weight can be adjusted from 30 up to 160 grams by means of an electronic sensor.

- Built-in flour duster with pressing unit.

- Equal distance between dough balls after cutting and maximum accuracy in weight.

- Integrated electric control panel (The service areas of the machines are easily accessible via safely guarded doors and panels.)

- Motor 1.5 HP with frequency inverter to enable cutting speed control.

- Extra features:

- LCD Counter

- Front cover can be opened for cleaning purposes.

- Protection features

- Hopper capacity 264 liters

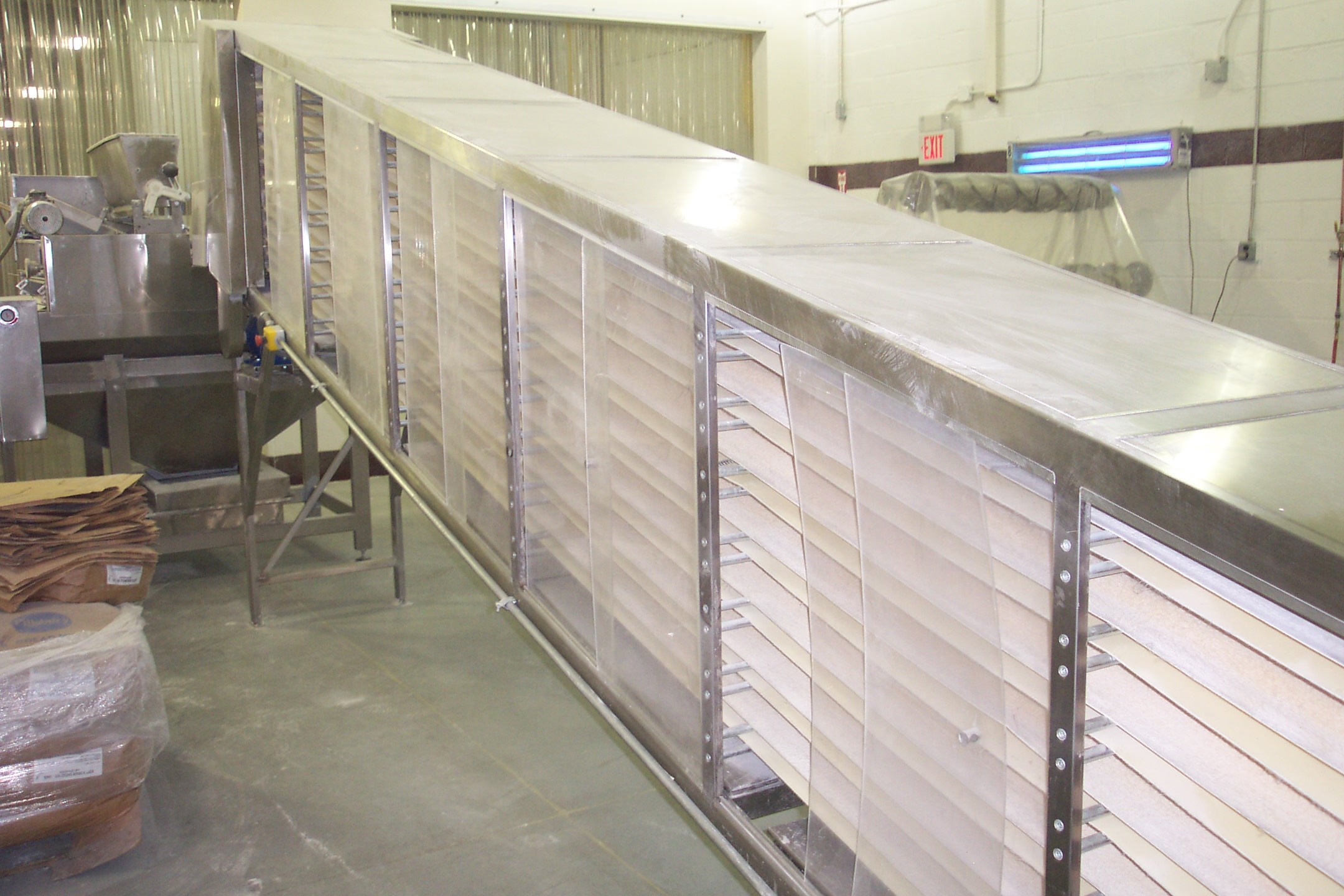

- Intermediate Proofer

- Model SIPT-560 AL

- Stainless Steel

- 7 Superimposed conveyor belts, 50 cm wide, 550 long

- Self-centering belt guides to ensure smooth tracking of the belts

- All belts are food grade quality, non-stick and long lasting

- Resting time of dough balls can be adjusted from 6 up to 30 minutes via motor 1.5 HP with frequency inverter.

- Plexiglas sliding lateral covers

- Integrated electric control panel (The service areas of the machines are easily accessible via safely guarded doors and panels.)

- Motor 1.5 HP with frequency inverter to enable cutting speed control.

- Extra features:

- Flour duster & pressing unit

- Sheeter

- Model SFE-3L

- Stainless Steel

- Three lane sheeting (3 rows)

- Electro-pneumatic type, activated by means of a sensor-detector

- Adjustable sheeting rollers to set dough sheet thickness, engineered for high precision dough sheeting

- Bearings are protected by dust & flour seals

- Two integrated stainless steel flour dusters to ensure spreading balance of flour from both top and bottom of dough sheets with minimum quantity required.

- Waste flour collector

- Scraper frames are of an extreme precision.

- No lubrication is required

- The first sheeting block is driven by a speed reducer motor; the second is driven by the final proofer with frequency inverter motor for an utmost synchronization

- Special food grade quality felt belts to allow minimum flour quantity on dough

- The machine can be easily operated and adjusted according to dough sheet thickness required

- Extra features:

- Additional flour collector

- Protection features

- Final Proofer

- Model SFP-9100L

- Stainless Steel

- 13 Superimposed endless conveyors, 900 cm long each, 100 cm wide

- Self-centering belt guides to ensure smooth tracking of the belts

- All belts are food grade quality and non-stick material

- Leavening time can be set from 8 to 40 minutes via motor 1.5 HP with frequency inverter

- Extra features:

- Plexiglass sliding lateral covers

- Bakery Oven

- Model SO-5204L

- Tunnel shaped, 520 cm long, supplied without burner

- Supplied with gas openings for both top & bottom burners

- High quality refractory bricks, strategically mounted to optimize baking performance

- Inner conveyor band, 100 cm wide

- In-feed conveyor on inlet of the oven 2.5 meters long included and its belt is well protected against radiating heat

- Bearings and housings are well protected and not exposed to excessive heat

- Adjustable exhaust opening to save maximum energy

- High grade refractory stainless steel plate on top of bread exit

- Stainless steel external body panels

- Equipped with a 1.5 KW motor with frequency inverter to enable baking speed control

- Extra features:

- Adjustable bread exit height

- Double insulation (with additional chimney) by means of hot air extraction

- Stainless Steel plates for the main conveyor

- Discharge Unit

- 100 cm wide, to prevent bread from turning upside down

- Cooling Conveyors

- Model SCA-210L

- 100 cm wide, 55 meters long, with double bars to ensure non-slipping of small size bread

- Combination of aluminum & stainless steel construction

- High quality hollow pin roller chains which minimizes chain stretching

- Engineered for flexibility and reliability in durable construction

- Low friction, practically noiseless & lubrication free

- Adjustable speed by means of frequency inverters

Inventory# 908GT0001

Get a Quote